Northrop Grumman continues to invest in defense microelectronics systems with the creation of its “Micro-Line” (μ-Line) in Apopka, Florida. The μ-Line establishes a wafer post-processing and test source tailored for defense applications.

The μ-Line facility for semiconductor wafer post-processing provides an assured source for the development and production of critical microelectronics packaging technologies.

Products processed at the μ-Line will serve as essential building blocks to some of the world’s most advanced radio frequency (RF) and electro-optic infrared (EO/IR) defense systems.

The μ-Line’s manufacturing equipment and personnel will deliver products that meet Northrop Grumman’s demanding quality and performance specifications.Northrop Grumman

The μ-Line’s manufacturing equipment and personnel will deliver products that meet Northrop Grumman’s demanding quality and performance specifications.Northrop Grumman

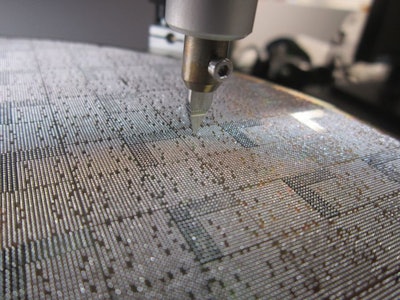

The μ-Line offers a suite of back-end wafer post-processing capabilities, including passivation, solder bumping, dicing, advanced inspection and test for up to 300 mm (12 inch) wafers. The capabilities are tailored to meet the stability, quality and security required by Northrop Grumman’s customers.

Semiconductors post-processed at the μ-Line will support both current and future Northrop Grumman programs leveraging advanced packaging.

The company also has semiconductor foundries in Baltimore, Maryland and Redondo Beach, California.