INDIANAPOLIS, IN — Würth Additive Group, a Würth Industry North America company and the leader in physical and digital inventory, announced March 18 that it has signed an agreement with Kurtz Ersa Inc., a technology and market leader in the fields of electronics production equipment, molding machines, and automation. The agreement expands the group's suite of 3D printing technology offerings by introducing the Alpha 140, which combines innovative additive manufacturing technology with simple operation at low system costs.

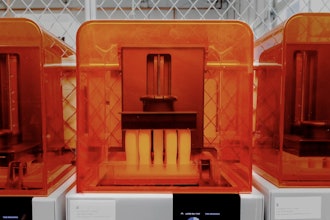

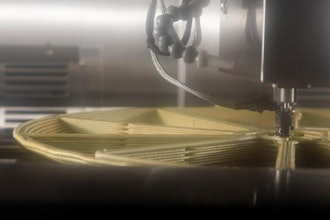

The agreement broadens Würth Additive Group’s ability to support high-end production through Kurtz Ersa’s proprietary Perfect Angle Printing technology. The Alpha 140’s fiber-coupled diode laser is guided coaxially to the powder bed, enabling a constant focus diameter across the entire build space and creating optimal properties for metal processing. Through innovative re-engineering, they have removed up to 40 percent of the machine’s cost and a historical point of failure seen on other systems making it a true plug ‘n produce machine.

“Kurtz Ersa and Würth have had a long and productive history as customer and supplier,” said Dan Hill, chief executive officer for Würth Industry North America. “By reimagining status quo inventory management, we can drive down costs, not by cutting corners but instead by intelligent engineering. We’re happy to support our customers through more efficient and profitable inventory solutions.”

“Kurtz Ersa has been creating well-built and sustainable products for over 200 years,” said AJ Strandquist, chief executive officer of Würth Additive Group. “The innovations they have brought to the market since 1779 are remarkable, from their initial business of a water-driven hammer to soldering, to molding equipment, they truly understand the needs of a manufacturing environment, and we are excited to present this innovation and technology to our customers.”

“Partnering with Würth Additive Group will give Kurtz Ersa Inc. a significant boost in bringing the Alpha 140 to the American market and Würth customers,” says Albrecht Beck, president and COO of Kurtz Ersa America. “The extensive knowledge and experience with metal 3D printing brought by Würth Additive Group, combined with Kurtz Ersa’s track record of producing market-leading technologies and top-rated service will allow us to elevate customer capabilities and support.”

Wurth Additive Group, led by CEO AJ Strandquist, launched in April 2021 to provide expanded industrial 3D printing products and services, including financing and rental options. Würth Industry North America began providing additive solutions to customers in late 2017 with rapid prototyping and printing production tools. It now offers complete digital Kanban solutions by integrating 3D printing technology in its existing vendor managed inventory programs. The group aims to streamline customers’ supply chain and increase adaptability through additive manufacturing and digital inventory.

Würth Industry North America (WINA) is a $1+ billion division of the Würth Group, the world’s largest industrial distributor. Within the Würth Group, founded in 1945, WINA is a privately held, family-owned business that believes collaboration and partnerships make business better. The company has strategically aligned, customer-centric market divisions, including industrial, MRO, safety, & metalworking, construction and specialty, that deliver better planning, parts management, and inventory accuracy. As global supply chain solution drivers, WINA offers total security through its products and services, including additive manufacturing, digital inventory, engineering assistance, quality control, inventory management, vending, safety supplies, kitting and assembly, structural fasteners, and MRO/industrial supplies. With more than 420,000 parts in their international supply chain, WINA provides each customer with an extensive global network and local knowledge from deep investment in its network of distribution centers across the United States, Canada, and Mexico.