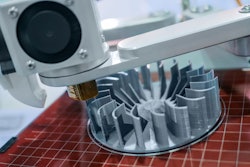

Researchers from Peter the Great St.Petersburg Polytechnic University (SPbPU) have developed and manufactured Prism, a unique 3D printer.

The 3D-printer was manufactured and first demonstrated on January 29, 2021. The main purpose of the developed printer is to print structures made of titanium, which is essential for various industries due to its strength properties and low specific weight.

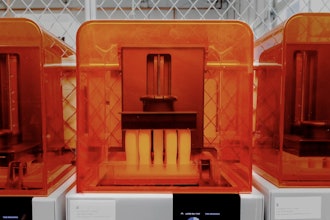

The printing system is located in a chamber with an inert atmosphere. This printer may also be used to print products made of steel, aluminum, magnesium, nickel alloys.

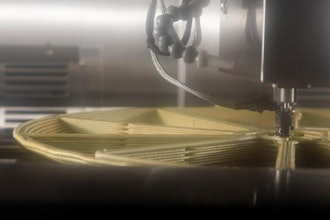

The researchers used the wire as a raw material to ensures the high productivity of the process. The layer-by-layer deposition is performed in the 3D printer, in which the wire is melted due to the burning of an electric arc.

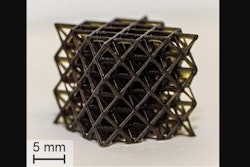

Two wires can be fed simultaneously to increase productivity and to synthesize new alloy or gradient structures from two dissimilar wires.

Concerning the numbers, German and Spanish companies are limited in wire feed rates at the level of 6 m/min, the printer developed at the Polytech University prints at the feed rate of 12 m/min.

3D printer for high-speed printing of titanium structures and in situ synthesis of alloys.Peter the Great St.Petersburg Polytechnic University

3D printer for high-speed printing of titanium structures and in situ synthesis of alloys.Peter the Great St.Petersburg Polytechnic University

"Our printer "Prism" has higher performance characteristics compared to the analogs. Due to the use of chamber with an inert atmosphere, we can print any metal, even very active like titanium. Also, the technology of printing itself were improved by the scientific group of SPbPU by developing a double wire feeding system and special shape of a current and voltage waveforms that used for electric arc burning.

"In fact, it is allowed to use two dissimilar materials during 3D-printing. Using two different wires helps to create innovative materials with gradient transitions in the structure or, for example, intermetallic compounds that are rarely used now due to the complexity of product manufacturing. Thus we can print a 4 kg titanium product within one hour. Our printer, due to the use of robotic arm, can be adapted for the needs of a specific enterprise, in particular, to increase or, on the contrary, to reduce its printing area," notes Oleg Panchenko, Head of the Laboratory of Light Materials and Structures SPbPU.

Scientists have already obtained several patents for the solutions used in the printer.