PITTSBURGH -- Researchers at Carnegie Mellon University report findings on an advanced nanomaterial-based biosensing platform that detects, within seconds, antibodies specific to SARS-CoV-2, the virus responsible for the COVID-19 pandemic. In addition to testing, the platform will help to quantify patient immunological response to the new vaccines with precision.

The results were published this week in the journal Advanced Materials. Carnegie Mellon's collaborators included the University of Pittsburgh (Pitt) and the UPMC.

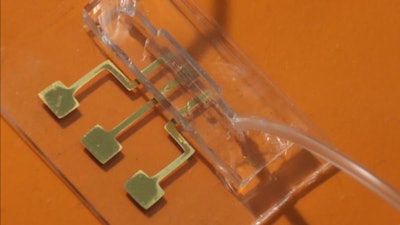

The testing platform identifies the presence of two of the virus' antibodies, spike S1 protein and receptor binding domain (RBD), in a very small drop of blood (about 5 microliters). Antibody concentrations can be extremely low and still detected below one picomolar (0.15 nanograms per milliliter). This detection happens through an electrochemical reaction within a handheld microfluidic device which sends results almost immediately to a simple interface on a smart phone.

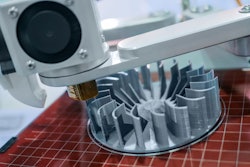

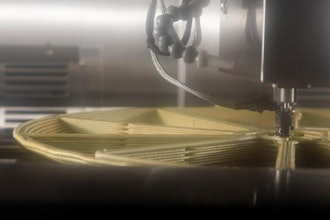

"We utilized the latest advances in materials and manufacturing such as nanoparticle 3D printing to create a device that rapidly detects COVID-19 antibodies," said Rahul Panat, an associate professor of mechanical engineering at Carnegie Mellon who uses specialized additive manufacturing techniques for research ranging from brain-computer interfaces to biomonitoring devices.

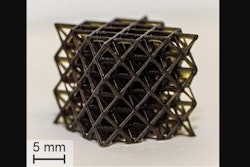

An additive manufacturing technology called aerosol jet 3D printing is responsible for the efficiency and accuracy of the testing platform. Tiny, inexpensive gold micropillar electrodes are printed at nanoscale using aerosol droplets that are thermally sintered together. This causes a rough, irregular surface that provides increased surface area of the micropillars and an enhanced electrochemical reaction, where antibodies can latch on to antigens coated on the electrode. The specific geometry allows the micropillars to load more proteins for detection, resulting in very accurate, quick results.

The test has a very low error rate because the binding reaction between the antibody and antigen used in the device is highly selective. The researchers were able to exploit this natural design to their advantage.

The results come at an urgent time during the COVID-19 pandemic. "Because our technique can quantify the immune response to vaccination, it is very relevant in the current environment," Panat said.

Panat collaborated with Shou-Jiang Gao, leader of the cancer virology program at UPMC's Hillman Cancer Center and professor of microbiology and molecular genetics at Pitt. Azahar Ali, a researcher in Panat's Advanced Manufacturing and Materials Lab, was the lead author of the study.

Rapid diagnosis for the treatment and prevention of communicable diseases is a public health issue that goes beyond the current COVID-19 pandemic. Because the proposed sensing platform is generic, it can be used for the rapid detection of biomarkers for other infectious agents such as Ebola, HIV, and Zika. Such a quick and effective test could be a game-changer for controlling the spread of diseases.