As the land of opportunity, America probably has more than its fair share of homegrown inventors, designers and manufacturers. For some, generation after generation express the family’s interest in and dedication to design and production. Their innovations have fueled technological improvements in every decade.

Case in point: The family of Daniel J. VanderPyl, President and Founder of Sonic Air Systems, Inc. of Brea, California. Dan can trace his manufacturing roots back to his great-grandfather, Frank Mossberg (1858-1953). Mossberg was one of the millions of immigrants who saw the promise of America, and he took her at her word. He became one of this country’s most prolific inventors, securing more than 200 patents for everything from a pencil sharpener used by schoolmarms to roller bearings which played a vital role in the industrial revolution.

Mossberg’s manufacturing odyssey began in 1882, when at age 24 he left his native Sweden for Massachusetts. He worked briefly as a draftsman before starting Mossberg Manufacturing Co. in Attleboro, Massachusetts in 1889. Mossberg’s business started at a time when bicycles were a significant form of transportation, and he initially focused on parts and tools for cyclists. This lead to his interest in bearing designs. Mossberg was awarded multiple patents in 1894 and 1895 for the first roller bearing designs which could be applied to miniature devices or scaled up to bearings capable of rotating loads to hundreds of thousands of pounds. In addition to improving the rolling mills in America’s brand new steel industry, Mossberg’s roller bearings helped join the Atlantic and Pacific oceans by ensuring that the massive locks of the soon to be completed Panama Canal would be able to rotate open or close with the least amount of resistance.

It wasn’t long thereafter that automobiles, electric, steam and gasoline engine powered, began to compete for the title of “best horseless carriage’. Mossberg immediately jumped feet first into the age of the auto by building his own electric car in 1898, but he quickly realized that there was a large field of companies trying to stand out in this new industry and the combustion engine was already winning favor. He turned his attention to designing and manufacturing tools for assembly and maintenance of whichever vehicle anybody had. Frank inaugurated the Mossberg Wrench Co. and in 1899, which was to dominate the American market for wrenches, automotive tools, and interchangeable socket sets for the next two decades.

At one time, his company sold more wrenches than all his competitors combined. But Mossberg’s genius lay in his rapid response to the birth of rapidly expanding technologies. He was soon patenting automotive service tools; in 1920, these became his forte.

Along the way, Mossberg became good friends with another inventor, Thomas Edison. Both men were avid inventors, churning out one idea after another to meet the needs of changing times. At one time, Mossberg was considered second only to Edison for the number of patents he held.

Mossberg’s roller bearings were later incorporated a key component of gun carriages in WWI sniper rifles and his bearing designs were later modified for use in heavy artillery and anti-aircraft used in both WWI and WWII.

In the 1930s, his company merged with APCO (The Auto Parts Company) and became APCO-Mossberg. In the 1930s, the company narrowed its focus to torque measurement products and continues on to this day. Together with Mossberg Industries, these are the two most obvious links to their founder.

Mossberg’s daughter and Dan's grandmother, Florence, married Chester A. VanderPyl, Sr. (1885 to 1959). Momentarily, the family’s inventive streak faltered. But it powerfully reasserted itself in the form of their son, Dan’s father, Chester A. VanderPyl, Jr.

VanderPyl was six years old when, due to his mother’s divorce, he moved into grandfather Mossberg’s house in Massachusetts with his mom and siblings. He lived there until he began college and his own career of invention, creation and manufacture.

The first 15 years of Chester’s engineering career, where he honed his manufacturing skills was with Metals & Controls Company of Attleboro, MA. The company later became part of Texas Instruments. In 1956, he was hired by Fram Corporation in nearby East Providence, RI to be the engineering manager for their line of automotive mufflers and reusable engine filter assemblies. With his tutorledge at the Mossberg factory during his teenage years and his experience at Metals & Controls, Chester was primed to make a major contribution at Fram Corp. At the time, Fram was a small company whose name was unknown outside of the automotive manufacturing world. The filters which Fram was making in the 1950’s, just as with their competitors, required car owners to regularly remove them, wash them in gasoline or kerosine and reinstall them. It was a time-consuming and messy process. In 1958, during his second year with the company, Chester completed the first design for what would become five patents which would forever change automotive filters, and filters in many other industries as well.

He developed the first disposable pleated media cartridge filters for oil, gasoline and air. He was soon promoted to V.P. of engineering at Fram where he and his design and manufacturing team contributed to making Fram filters a household name across the world.

Chester VanderPyl became V.P. of the STP Corp. in 1971. In 1976, the owners of STP (that would be the Granatelli brothers of Indy and NASCAR racing fame) asked him to become the G.M. for their supercharger manufacturing company in California, Paxton Products. At Paxton he developed the high speed belt driven centrifugal blower for a growing industrial blower market. He was closely flanked by his son, Daniel VanderPyl, who had worked at Paxton since his high school days. Chester passed away from cancer in 1983, but Dan stayed on with Paxton where he was instrumental in developing the high velocity air knife business along with becoming an air application engineering specialist in the blower industry. VanderPyl stayed on with Paxton as the industrial products sales manager, until Dan and fellow Paxton design engineer Terry Riley decided to strike off on their own in 1990.

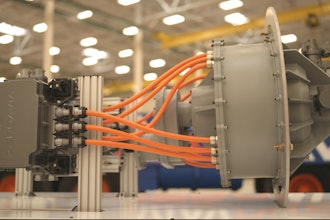

After forming Sonic Air Systems in 1990, with VanderPyl as the president & chief technologist and Riley doing the design and manufacturing engineering, Sonic was utilizing Paxton blowers as part of Sonics complete air systems. Then in 1992 a shift in sales strategy by Paxton forced VanderPyl and Riley to engineer the Sonic Air centrifugal blower, and the rest as they say is history. Ironically, Sonic’s first engineered product harkens back to Chester’s successes with Fram Corp as the Sonic integral filter/silencer assembly for industrial blowers. Sonic created the industry’s first integral air filter/silencer assembly with vacuum gage. The original patent for Chester’s pleated disposable filter cartridge had long since expired and Sonic’s filter element supplier was now using the same technology.

The Chester’s influence came back again when VanderPyl & Riley designed the 20,000 RPM Sonic blowers to reduce the number of components thereby improving overall reliability.

Sonic’s contribution to During our first 25 years, Sonic has sold over 40,000 of these filter/silencer assemblies, mostly for use on Sonic blowers but frequently on our competitors blowers as well. This new and improved Sonic Air blower design came of age in response to the 1989 Exxon Valdez oil spill disaster in Alaska. The U.S. congress had passed ocean waters protection legislation in 1990, but it wasn’t until 1992 when Sonic Air Systems was asked by the new Marine Spill Response Corporation to quote on the development of a custom blower design for shipboard oil boom air inflation duties. Sonic blowers were ultimately chosen for two different MSRC contracts through 1994 with a total of (90) rapid deployment air inflation systems. Those original Sonic blower systems were most recently deployed by MSRC as part of the response to the massive 2010 B.P. Oil spill in the Gulf of Mexico.

Despite Sonic’s contribution to the oceans protection duties, it was really the environmental necessities of the 1987 Montreal Protocol which spurred on the demand for Sonic blower and air knife systems worldwide. The foundation of Sonic's original business plan was to develop blower powered air knife systems which would address the drying needs created by the worldwide phase out of CFC’s, as mandated by the Montreal Protocol, and the subsequent conversion to water based products as a replacement technology. It wasn’t long before Sonic blowers were drying the majority of p.c. boards being manufactured in the U.S. in the 1990’s.

In 1995 VanderPyl then saw the need for a new highly efficient air delivery device to complete the drying of p.c boards and other products, so he and Riley designed the Sonic XE Air Knife. It was the first single piece extruded “tear drop” shaped air knife in the industry with the coefficient of discharge being .95 aka 95% efficient. And so began the development of an entire product line of blowers, air knives and other air delivery products which are now the standard of the blower and air knife industry.

VanderPyl has two current patented products, the self propelled Rotary Air Knife and the heater-less hot air blower design. Both have revolutionized the drying of manufactured products on conveyors and after C-I-P washing of tanks and containers throughout food and pharmaceutical production facilities. With Sonic’s focus now shifted from chemical replacement technology to energy reduction, VanderPyl’s blower and air knife designs are proving to meet those challenges too.

Like his great grandfather Frank Mossberg started 125 years before him, Dan VanderPyl continues to design products to meet the needs of an evolving world.

For more on Sonic Air Systems, visit www.sonicairsystems.com.